Discover Smart Effects, where innovation meets sustainability. Our advanced solutions, leveraging the synergy of silica and silanes, cater to diverse industries including green mobility, electronics, and carbon capture. By utilizing cutting-edge technologies and efficient processes, Smart Effects delivers exceptional value and performance. We are committed to driving positive change with eco-friendly products that benefit both our customers and the planet.

Join us in shaping a smarter, greener future with Smart Effects.

🌟 Exciting News from Evonik! 🌟

We are thrilled to announce the launch of Smart Effects, effective 1 January 2025! The new business line is a new entity born from the strategic merger of its Silica and Silanes business lines marking a significant step forward in our commitment to delivering innovative and sustainable solutions to our customers across diverse industries.

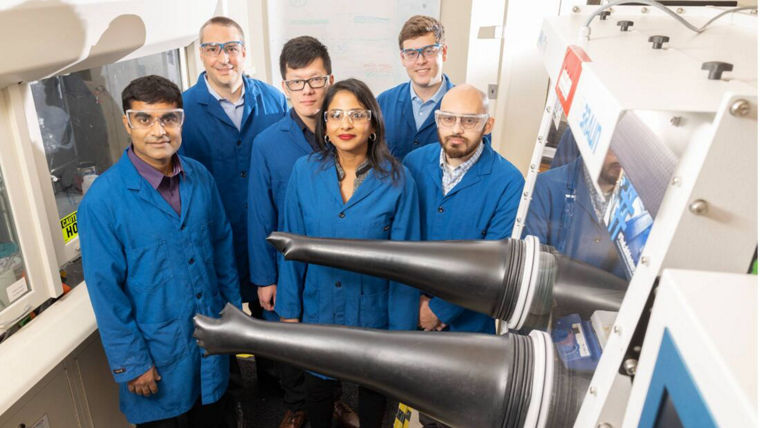

With a team of worldwide 3,500 employees, Smart Effects will streamline operations and enhance our offerings in key markets such as automotive, electronics, consumer health, and building protection. Our integrated approach combines the strengths of molecular silane chemistry and silica particle design, enabling us to create tailored solutions that add real value.

Smart Effects is not just about chemistry. We go beyond in industry: From elements to excellence. Join us on this exciting journey as we aim to improve life today and tomorrow.

Silica is safe

Safety matters. To us and to you. Why Evonik is convinced that synthetic amorphous silica is safe to use: Find concise information, FAQ and scientific studies about this naturally derived substance.