EXTREMELY POWERFUL: EVONIK's SILICA AND METAL OXIDES FOR BATTERIES

Electronic devices and cars need batteries to run. And Evonik gives batteries their power. Our high-quality pure AEROSIL® fumed silica and AEROXIDE® fumed metal oxides increase the performance of lead-acid batteries and of lithium-ion batteries (LIB) in electronics and electric vehicles (EV).

Innovative battery technology is now more important than ever because it is the key to realizing climate-friendly electromobility across the globe. With our Next Generation Solutions, EV battery manufacturers can optimize the performance of batteries in terms of both safety and driving distance.

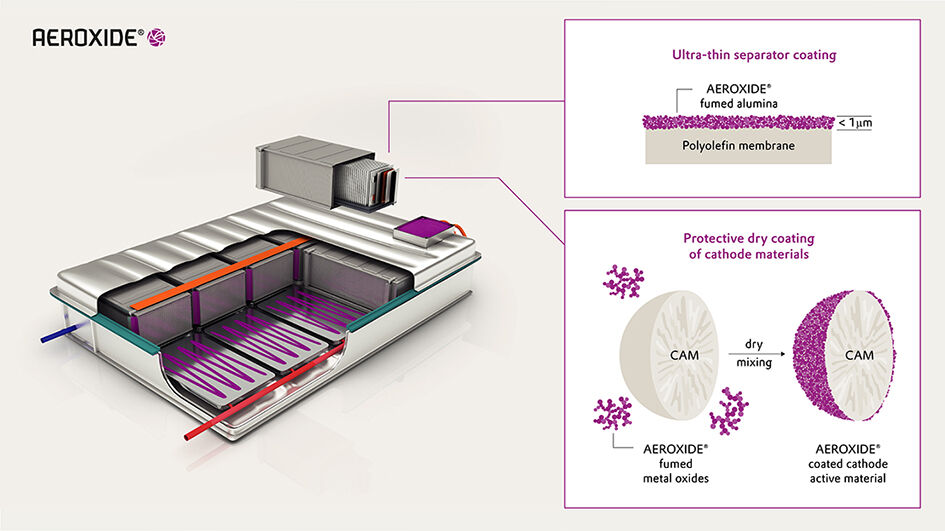

AEROXIDE® products are used in several in-cell applications: Dry coating of cathode active materials with AEROXIDE® fumed metal oxides improves the performance and lifetime of lithium-ion battery cells. And in high-performance LIB separators, AEROXIDE® fumed alumina can be used for ultra-thin, homogeneous ceramic separator coatings or as ceramic filler inside the membrane, resulting in higher thermal stability of separators. Evonik also offers AERODISP® – ready to use alumina dispersions, tailor made for specific coating application and compatible with a variety of different binders.

Evonik’s research and development teams continuously work on clever solutions for the next generation of lithium-ion batteries for electric vehicles. Battery manufacturers are exploring new battery pack designs without module housings, known as “cell-to-pack” (CTP) design. This approach reduces weight, increases energy density, lowers cost, and simplifies manufacturing. AEROSIL® fumed silica, AEROXIDE® Alu and AEROXIDE® TiO2 PF 2 can contribute to innovative formulations for thermally stable silicone, thermally conductive adhesives, and thermal insulation materials.

Key benefits of Evonik’s silica and metal oxides for batteries

- Improved performance, enhanced safety and longer lifetime for lithium-ion batteries

- Efficient pore generators in PE separators for lead-acid batteries

- Longer lifetime of stationary lead-acid batteries through effective electrolyte gelling

Experts in particle design

We are one of the global leaders when it comes to nanostructured particle design of metal oxides as additives and in the development of new silicas as components for batteries.

Excellent processability

Our additives are characterized by high chemical purity and good processability. We also offer specifically designed ready-to-use fumed metal oxide dispersions for battery applications.

Tailor-made solutions

We support our customers closely and understand their processes and needs. Together, we develop tailor-made solutions for their battery products.

LEAD-ACID BATTERIES

Precipitated silica from Evonik, such as SIPERNAT® 325 AP, is the main component of PE separators for lead-acid batteries in cars. Fumed silica (AEROSIL® 200 V) is applied during the production of gel electrolytes in stationary lead batteries to increase the lifetime of the battery.

LITHIUM-ION BATTERIES (LIB)

Lithium-ion batteries (LIB) have become indispensable in consumer electronics and computer technology and are now an inherent part of our everyday lives. Moreover, they enable sustainable technologies for a greener future, such as electromobility and the rapidly growing market for renewable energy storage systems. Whether they are used in a smartphone or an electric vehicle, the function of lithium-ion batteries is always the same – and so are the challenges: handling high energy density and offering a long service life with thousands of charging cycles.

Whether miniature or large, lithium-ion batteries benefit from Evonik’s metal oxides in many ways:

AEROXIDE® fumed alumina can be used either as a ceramic coating on top of the polymer separator or as additives inside the separator to increase the safety of the battery cell. A dry coating of fumed aluminum oxide (AEROXIDE® Alu 130) or fumed titanium dioxide (AEROXIDE® TiO2 P 25) on the cathode active materials increases battery durability and performance. Fumed aluminum and titanium oxides, preferably hydrophobic AEROXIDE® Alu C 805 and AEROXIDE® TiO2 T 805, can be used in next generation polymer electrolytes.

EV BATTERIES

The shift from gasoline-powered combustion engines in cars to hybrid and fully electric vehicles (EV) has put lithium-ion batteries at the heart of modern electromobility. High demands exist for lithium-ion batteries in electric vehicles: They must feature a very high energy density, exhibit a suitable fast charge ability, and provide enough power for a long driving range while also meeting stringent safety requirements. Therefore, high-performance materials need to be used for the electrodes, within the separator, and in the electrolyte of EV batteries.

Evonik provides experience and expertise, as well as high-performance AEROXIDE® metal oxides, AERODISP® fumed alumina dispersions and AEROSIL® fumed oxides for applications in EV battery cells and battery packs.

AEROXIDE® products in in-cell applications for EV batteries

In-cell applications:

- Separator coating: A very thin layer of AEROXIDE® fumed alumina limits shrinkage of the membrane at higher temperatures. This helps to prevent thermal runaway and improves the safety standards of lithium-ion battery cells. Ready-to-use AERODISP® fumed alumina dispersions enable the preparation of these ultra-thin (≤ 1 μm), homogeneous ceramic coatings, which is not possible using conventional coarser particles.

- Ceramic filler inside the separator: nanostructured fumed aluminum oxide as filler results in excellent mechanical and thermal membrane properties combined with a high porosity. This enables the manufacturing of very thin separators ( ≤ 10 µm) with a high safety.

- Cathode active materials: Dry coating with AEROXIDE® fumed metal oxides stabilize cathode active material particles and help to avoid cracks during charge and discharge. This significantly increases the rate capability and capacity retention of lithium-ion battery cells and therefore the overall lifetime of the battery.

- Solid-state batteries: Fumed aluminum and titanium oxides, preferably the hydrophobic variants AEROXIDE® Alu C 805 and AEROXIDE® TiO2 T 805, can be used as components in next generation in solid-state polymer electrolytes.

Battery pack assembly:

- AEROSIL® fumed oxides provide excellent rheological and reinforcement properties in EV battery structural adhesives.

Battery Performance Innovations

Evonik solutions for battery electric vehicles: battery pack, battery cell and battery management systems.

NextGen Sustainability Impact

AEROXIDE® fumed metal oxides enhance the performance of lithium-ion batteries in electric vehicles and save CO2.

NextTech Applications

Enhancing lithium-ion batteries with high-quality fumed alumina dispersions.

More information

Evonik’s product portfolio for electric vehicle batteries includes a wide range of chemistries and high-performance materials. With raw materials, additives, process enablers and ready-to-use dispersion, our products improve the performance of our customers’ battery products across the entire value chain for EV batteries, wherever it is needed: battery packs, battery cells, battery management systems and battery recycling. And with our Next Generation Solutions, we make electric vehicle batteries safer and more durable.

Discover our full range of automotive products and solutions in Evonik’s automotive industry information hub