Evonik SIlica Solutions

Silica from Evonik are real all-rounders. They help our customers to make good products even better. In many areas of everyday life, they serve as pouring aids, carrier substances or defoamers. They optimize the flow capability of fluids and improve the storage properties of powders. Our fumed and precipitated silica can be tailored to precisely fit your requirements. Discover the wide range of fascinating effects here.

Dispersions

For customers that encounter difficulties using powder products, fumed oxide dispersions provide a solution. Evonik not only has extensive knowledge but also sophisticated equipment, both are necessary to produce high-quality silica dispersions as well as TiO2 and alumina dispersions.

ANTICAKING

Even after storage and transportation, powders needs to remain pourable without caking. SIPERNAT® specialty silica and AEROSIL® fumed silica ensure good storage time stability and prevent caking.

CARRIER

Not every liquid is easy to process. Viscous or sticky liquids are particularly problematic, for example when it comes to dosing. SIPERNAT® specialty silica or AEROPERL® granulated fumed absorb liquids like a sponge and transform them into pourable powders.

FREE-FLOW

Powders that do not pour easily are difficult to use or process. Adding SIPERNAT® specialty silica or AEROSIL® fumed silica from Evonik makes powders especially pourable, free flowing and therefore easy to dose.

RHEOLOGY

Stable when stored, easy to stir during processing – and stable again after application: Dispersions of finely distributed solids have to meet different requirements depending on the situation. AEROSIL® fumed silica enables the rheology of fluids to be adjusted.

ANTISTATIC

If powders or granulates are subjected to friction, for example when they are transported through pipes or mixed, they can become electrically charged. Fumed alumina products reduce electrostatic charging and improve processability.

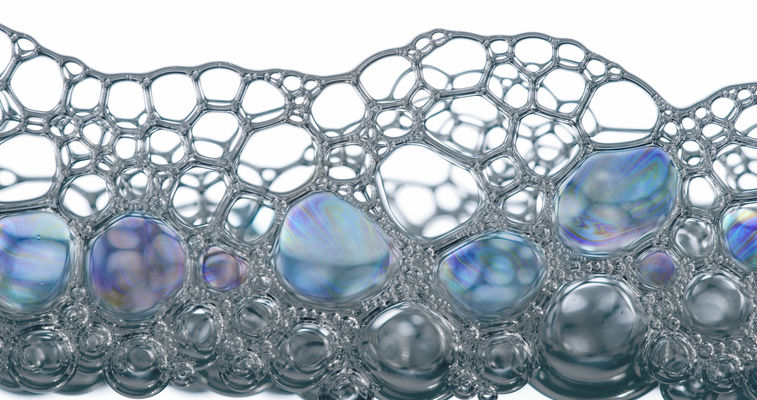

DEFOAMER

Foam can be disruptive – for example in manufacturing or applying products. Defoamers can provide relief by effectively controlling foam formation. SIPERNAT® specialty silica and AEROSIL® fumed silica are important components in defoamers.