Antistatic

If powders or granulates are subjected to friction, for example when they are transported through pipes or mixed, they can become electrically charged. Fumed alumina products reduce electrostatic charging and improve processability. Evonik has several AEROXIDE® products that create this antistatic effect.

Fumed alumina from Evonik reduces electrostatic charging in powders.

Pigment powders are susceptible to electrostatic charging, making them more difficult to process. AEROXIDE® fumed alumina help retain the flowability of the powder.

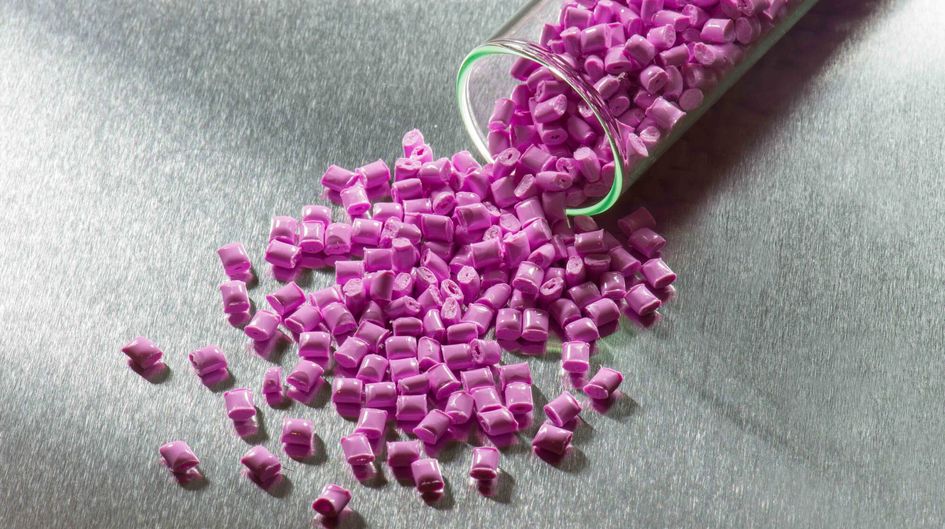

Electrostatically charged polypropylene granulates without AEROXIDE® Alu C (left) adhere to the glass wall – an undesired effect in many cases.

Polymer granulates are particularly prone to electrostatic charging. AEROXIDE® fumed alumina can help to neutralize the charge, which is known as an anti-static effect.

Many non-conductive powders become electrostatically charged when subjected to friction, for example when a polymer powder or granulate is transported through a pipe or agitated in a mixer. The charged powder then adheres to the walls of the pipe or mixer and cannot be transported or discharged.

Adding less than 0.1% of AEROXIDE® fumed alumina neutralizes this charge, enabling powders to be dosed more precisely and avoiding expensive downtimes. At the same time, the quality of the product is increased.

Many synthetic polymers have a high electron affinity and become negatively charged. In contrast, fumed alumina becomes positively charged. Alumina is also very finely dispersed and mixes well with other powders or granulates. If a small amount of an AEROXIDE® product is mixed with a polymer granulate, the alumina is distributed over the surface of the granulate and covers the individual granulate particles. The opposing charges neutralize each other and the granulate can flow freely.

AEROXIDE® alumina products are easy to handle. Similar to flow additives, simply mixing using a plowshare mixer, paddle mixer or belt mixer is sufficient.

Plastics flyer, Plastics fact sheet, TO AEROXIDE®