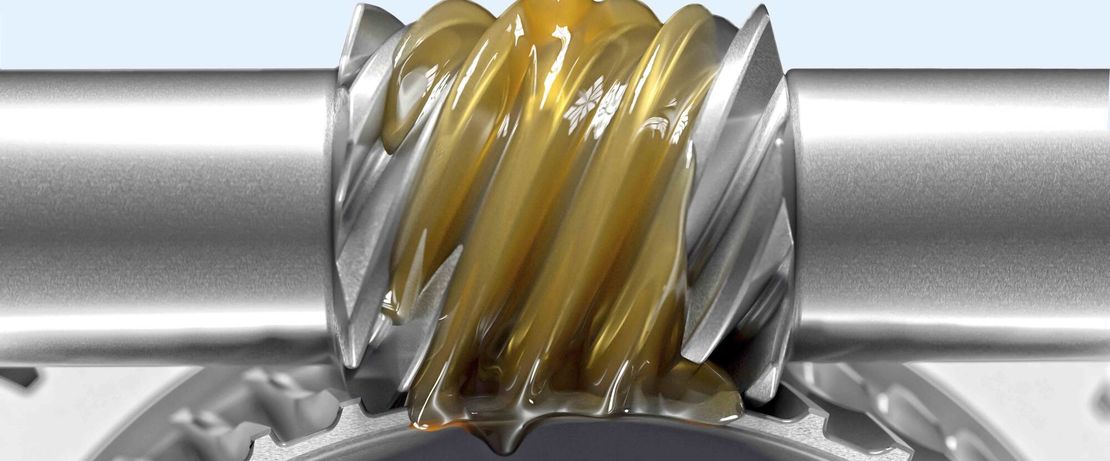

Perfectly lubricated: Create high-quality lubricants and greases using silica

As additives or thickeners, our silica not only improve the performance, but also the shelf life of your products. With diverse applications and highly effective: Silica from Evonik improve lubricants and greases.

In lubricants and greases, the details decide whether everything runs smoothly. Only then can the optimum quality be achieved. After all, the lubricants must perform reliably even at the highest temperatures and pressures. Silica help producers precisely specify the desired viscosity. And our silica can do much more: They ensure better oil separation, or, when used as an additive, they can improve different parameters – from mechanical stability to heat resistance. In metal processing materials, they control the rheology and stabilize lubricating solid particles.

There is no doubt that the demands placed on lubricants or greases are high – whether in industrial plants, or in the automotive or electronics industries. The diverse hydrophilic and hydrophobic AEROSIL® fumed silica products from Evonik enable you to meet the highest demands.

Advantages of the silica for lubricants and greases

- Optimum rheology control: Set the viscosity of your lubricants and greases

- Flow limit and thixotropic effects can be optimized in the best possible way

- As additives, silica modify the friction properties

- They also increase mechanical stability

- Oil separation in lubricants and greases is optimized

- Improvement of temperature stability (dropping point)