Rheology

Stable when stored, easy to stir during processing – and stable again after application: Dispersions of finely distributed solids have to meet different requirements depending on the situation. AEROSIL® fumed silica enables the rheology of fluids to be adjusted so that dispersed solids do not settle and paints do not run off a wall upon application, for example. Despite this, the fluid remains easy to process.

AEROSIL® FUMED SILICA FROM EVONIK ENSURES STRUCTURAL VISCOSITY AND THIXOTROPY

AEROSIL® fumed silica ensures that silicone sealing masses remain in place after application.

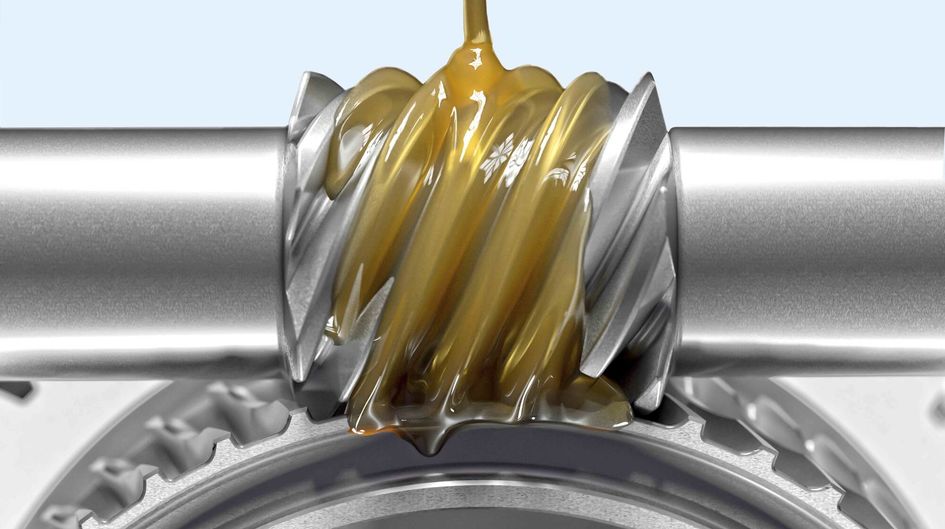

AEROSIL® fumed silica helps adjust the viscosity of lubricants.

A stored dispersion without AEROSIL® fumed silica (left): The particles settle; with AEROSIL® fumed silica, they remain floating in the suspension (right).

Important in rotor blade production: AEROSIL® fumed silica ensures stable thixotropy of adhesives. The silica also prevents filler materials from settling and enables viscosity inspections of 2K systems.

Without the addition of AEROSIL® fumed silica, the paint runs off the surface (left). With AEROSIL® fumed silica products, the coating remains stable (right).

Numerous application areas require dispersions of finely distributed solids. However, it is vital that these dispersions remain stable and do not settle when stored. Paints and coatings should not run. To fulfill these requirements, high viscosity alone is not enough. The dispersion must have a yield point and display thixotropic behavior. This means that the fluid displays gel-like properties when stored and the dispersed particles remain permanently stable.

Upon shearing, the fluid becomes less viscous and is easier to process. When the shearing stops, the dispersion recovers its structure and becomes stable again. AEROSIL® fumed silica products from Evonik achieve this behavior in the best possible way. The broad portfolio of hydrophilic and hydrophobic AEROSIL® fumed silica types provides the ideal product for any formulation.

When AEROSIL® fumed silica is added to a fluid, it disperses into fine aggregates. These aggregates have a branched structure and are able to create a three-dimensional network with neighboring aggregates and other components in the fluid.

When stored, this network provides the fluid with a gel-like structure and keeps dispersed solids floating in the suspension. In addition, the fluid does not flow downwards, even on vertical surfaces. Stirring or shearing the fluid breaks up the network and the AEROSIL® aggregates move freely in the fluid.

This process is reversible: If the fluid is left alone, the AEROSIL® aggregates come together to form a network and the product becomes stable again.

To achieve the optimum effect, AEROSIL® fumed silica products should be dispersed well in the fluid phase. Rotor-stator systems or dissolvers are ideal for this. Allowing the product to be held in a bead mill for too long is excessive processing that can result in the irreversible fragmentation of AEROSIL® aggregates and a reduction in the rheological properties.

The polarity of the fluid phase also has a major impact on the efficacy of AEROSIL® as a rheology control substance. In combination with AEROSIL® fumed silica products, other additives, such as wetting agents, can also influence the rheology. Our applied technology will be happy to advise and assist you in selecting the best AEROSIL® fumed silica product for your system.

You can find more detailed information on this topic in our Technical Information Sheets Technical Overview AEROSIL®, TI 1125, TI 1209, TI 1253, TI 1373, TI 1380 and TI 1396, TB 28, TB 63.