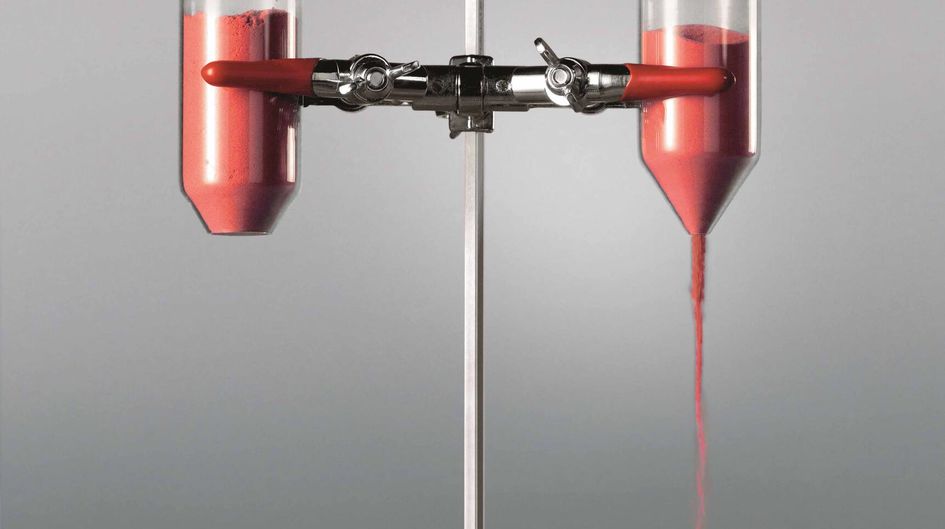

The free flow effect: Evonik silica improve powder flowability

Powders that do not pour easily are difficult to use or process. Adding SIPERNAT® specialty silica or AEROSIL® fumed silica from Evonik makes powders especially pourable, free flowing and therefore easy to dose. This is known as the free flow effect.

SILICA FROM EVONIK IMPROVES THE Free Flow effect OF POWDERS

Adding AEROSIL® fumed silica makes spice powders free flowing. Evonik offers AEROSIL® fumed silica types that meet the particular hygiene requirements of the food industry. HACCP certification can be provided if needed.

SIPERNAT® specialty silica and AEROSIL® fumed silica improve free flow of products.

Adding SIPERNAT® specialty silica improves the flow capability significantly.

The fluidization ability of fire extinguishing powder can be improved with SIPERNAT® specialty silica.

Adding SIPERNAT® specialty silica keeps washing powder easy to dose.

Pourable powders, or those with good flow capabilities are easier to dose, handle and process. A familiar everyday example is table salt, which needs to flow easily from the salt cellar. The free flow effect is particularly important in automated processes.

For many powders, it is not only the current flow capability that counts – they also need to remain pourable without caking during storage and transportation. This is known as anticaking or the anticaking effect .

The flowability of powders is influenced by the adhesive forces between the powder particles. The finer the powder, the stronger the adhesive forces. Fine-particle powders therefore have an inferior flowability than coarse powders.

A liquid film can also form on the surface of powder particles – for example in moist or oily particles – and hold them together through surface tension.

SIPERNAT® specialty silica and AEROSIL® fumed silica products consist of fine silica agglomerates that envelop the particles of the powder to be treated. In doing so, they act as spacers between the individual powder particles, separating them from one another and reducing the adhesive forces. They can also absorb any liquid film that exists.

Fine-particle SIPERNAT® specialty silica and AEROSIL® fumed silica products can be incorporated into the powder to be treated – known as the host powder – simply by mixing. Suitable mixers include plowshare mixers, paddle mixers, and belt mixers.

While a short yet intense mixing process is recommended for dry host powders, particularly gentle mixing is needed for moist host powders. This retains the porous silica structure so that the liquid can be absorbed from the powder as effectively as possible.

You can find more detailed information on this topic in our Technical Information Sheets TI 1213, TI 1351 TI 1360 and TI 1365.