Invented to improve: Our multitalented AEROSIL® Fumed Silica turns 80!

AEROSIL® from Evonik has been proving useful in practically every area of day-to-day life since 1942. Our branded fumed silica can now be found in more than 100 different products – in a wide variety of everyday items as well as in high-tech applications: from toothpaste to car batteries. And they all have one thing in common: even small amounts of the fluffy white powder make a big difference.

Now, at age 80, AEROSIL® continues to offer new solutions for applications that its inventor, Dr. Harry Kloepfer, did not even dream of, such as microchips.

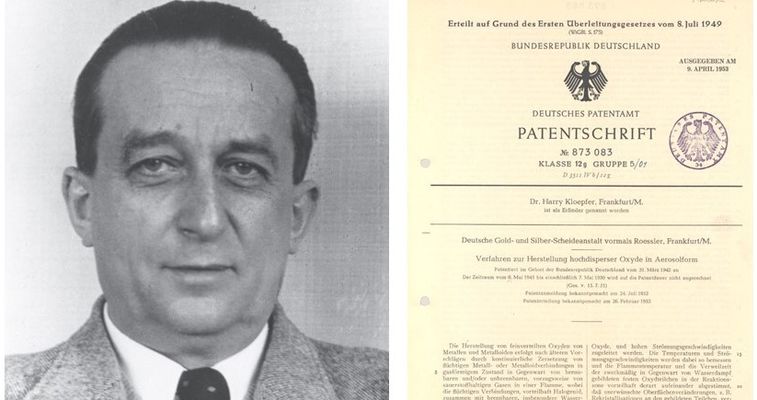

Dedicated chemist and man of action

Dr. Harry Kloepfer (1897 – 1973), who gained his doctorate from Berlin Technical College in 1922, was a leading researcher at Degussa, the predecessor of Evonik’s Chemical Business Area. He was a dedicated chemist with a gift for inspiring and motivating his staff. And he was a man of action who, before a new plant was commissioned, would crawl through the pipes himself, checking everything.

The beginning of a success story

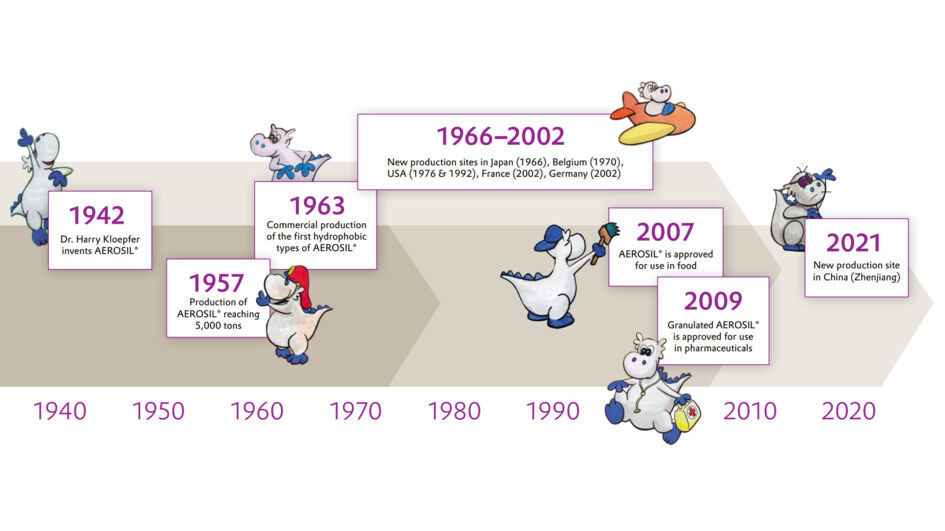

When Kloepfer invented a process for producing an extremely fine silica in 1942, he had no idea that this would mark the first chapter of an extraordinary success story that is continuing to this day. The chemist had originally developed the substance as an alternative to carbon blacks as a reinforcing filler for car tires , but it turned out to be a trailblazer for many more applications. Kloepfer’s fumed silica was registered under the trade name AEROSIL®. Since then, the product has been continuously developed and many new variants have been added to the product range.

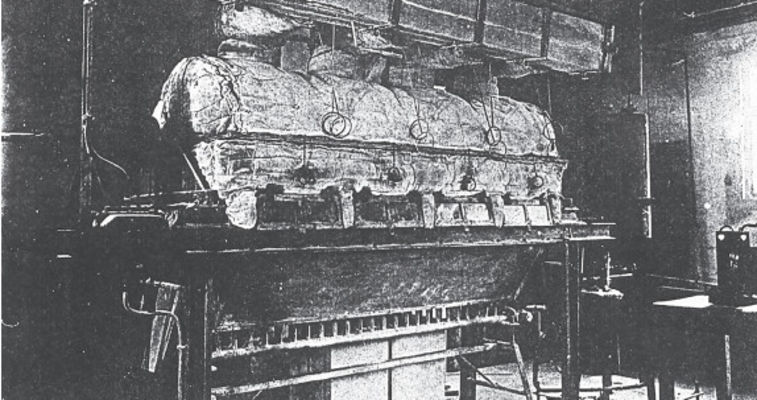

The world’s first fumed silica reactor

Dr. Harry Kloepfer developed high-temperature hydrolysis, which made it possible to produce an extremely fine silica particle. The first technical solution for manufacturing AEROSIL® was the roller process. Degussa obtained the first patent for the process and commenced industrial production of AEROSIL® in 1944. In 1952, a new FK reactor was built in Rheinfelden.

AEROSIL® milestones

AEROSIL® makes a difference in many applications

Today our AEROSIL® portfolio covers a wide range of surface areas as well as very different surface chemistries. Fumed silica is now used to optimize products in many different sectors of industry from tires to pharmaceuticals: AEROSIL® ensures that toner doesn’t clump, teeth get whiter, silicones don’t tear, coatings stick, walls are insulated, adhesives hold longer, concrete hardens better, and much more.

AEROSIL® fumed silicas help to...

…give toothpaste the right consistency so that it can clean teeth better.

…make pesticide use efficient and to formulate new pesticides.

…keep finely grained powdered spices free-flowing and without lumps.

…make silicones transparent and especially tear-resistant.

…stabilize cosmetics and give them a pleasing consistency.

…prevent the electrolytes from seeping out of gel batteries.

…ensure that toner is applied to paper with great precision.

…process plastics and make them more transparent and versatile.

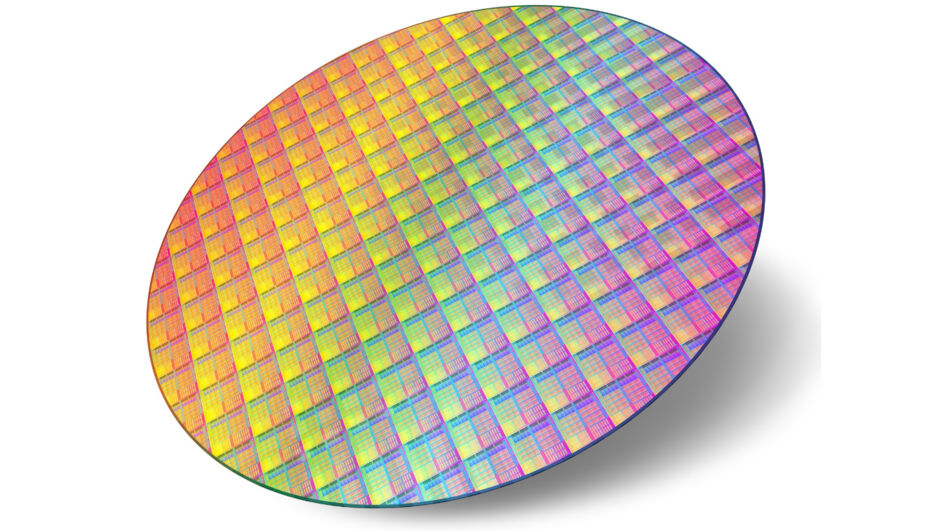

…finely polish silicon wafers for making microchips.

…formulate and dose medications and active ingredients.

…prevent drops from forming in high-speed printing machines.

…control rheological behavior of coatings and inks and provides brilliant appearance.

AEROSIL® fumed silica is characterized by one thing in particular: Evonik’s value-added-product philosophy. This philosophy is driven by a set of service components which complement each other and work together perfectly to contribute to achieving enormous effects with aggregated particles.

AEROSIL® advertising campaigns in the spirit of the times

“Drippig is undesired and costly” – graphic design in the 1950s.

Multi-talented AEROSIL® – advertising campaigns in the 1960s and 1980s.

1966: A tortoise as metaphor for longevity, thanks to AEROSIL® in rubber goods.

1972: AEROSIL® for thixotropy control in laquers, paints and varnishes – of course in the 1970s favourite colour: orange.

All you need to know about AEROSIL®: The series “Basic Characteristics and Applications of AEROSIL®” was first released in 1967. Part 1 of the series, entitled “Basic characteristics of AEROSIL® fumed silica”, was later integrated into the Fine Particles series of publications, as text number 11.

The present work, entitled “AEROSIL® – Fumed Silica,” is the eighth edition of this standard reference, and has been fully revised. It contains information on the physical and chemical properties of AEROSIL® and its potential applications.

From stomping on bags to high-tech compaction

Our expertise is not only focused on applications, but also on packaging and handling according to contemporary requirements. Currently, Evonik offers AEROSIL® in standard paper bags, flexible intermediate bulk containers (FIBC), silo transport, thermal packaging, and compaction technology. Can you imagine that people once used to jump on bags to compress the fluffy AEROSIL®?

Looking back at 80 years of AEROSIL®: historical photos

1954: No more dancing on the bags! One year earlier, a press screw was developed that compressed AEROSIL® using a vacuum, making filling much easier. Until then, colleagues had to jump up and down on the bags to compact the powdery silica. No wonder they called them Samba bags!

1963: A burner used for producing fumed silica in Rheinfelden. The raw material for all silica is raw silicon, which is obtained from pure sand. This is used to produce tetrachlorosilane, which reacts with the resulting water from an oxyhydrogen gas flame (comprised of hydrogen and oxygen) under high heat. This results in fumed silica with fine particle size: AEROSIL®.

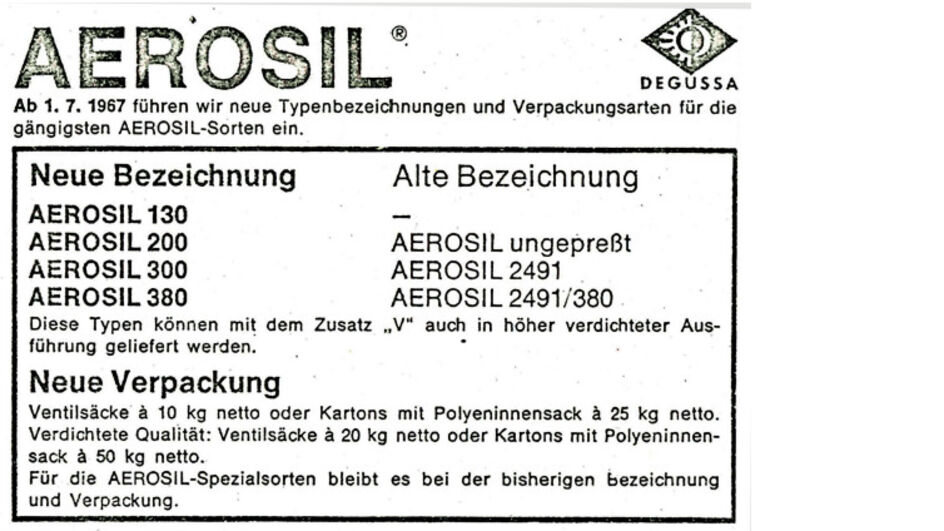

1967: The AEROSIL® family is growing and receives new type designations.

1960s: With their case of samples in tow, colleagues from the sales department introduce the different AEROSIL® varieties to customers.

1996: AEROSIL® gets a new look. The bags now have a vibrant, colorful design – a real eye-catcher in the warehouse.

2004: This forklift truck from 1966 enjoys a well-earned retirement. Bags are now stacked on pallets fully automatically.

How AEROSIL® bags have looked over time since 1968.

2017: Evonik standardizes the silica division’s brand identity for a contemporary design. AEROSIL® bags with the new font found on all our silica brands that customers have become familiar with to this day.

3 surprising facts about AEROSIL®

- Dry Water

If you mix AEROSIL® with water, you don’t get mush, but powder. That’s because the particles enclose tiny drops of water, which seep out when the powder is rubbed.

- Reaching up to the moon

If the primary particles in a pinch of AEROSIL® 300 were laid next to one another in a row, they would stretch from the Earth all the way to the moon.

- Safe food ingredient

AEROSIL® is not only legally approved for use in food, but also considered Kosher according to Jewish and Halal according to Muslim dietary regulations.

Meet our mascot Aerosili

Who remembers Aerosili? Our charming mascot accompanied the product for about ten years. The Aerosili calendars and cuddly toys were highly treasured by colleagues and customers.

AEROSIL® production sites – then and now

To explore, click here

The future of AEROSIL®

AEROSIL® has contributed tremendously to making life easier for all of us – it creates significant effects with just a small dosage. And Evonik’s silica experts are committed to continually creating new AEROSIL® products that boost innovation and support the growth of our customers’ business around the world.

We are your silica expert – Inside, to get it right.